Cross-linked shrink film is a high-quality, reliable, and cost-effective packaging material with excellent transparency, shrinkage, strength, and durability. In this article, we will provide a detailed description of the characteristics, advantages, and application fields of our cross-linked polyolefin shrink film.

Cross-linked shrink film is a special type of shrink film whose molecular structure has been made more stable and durable by cross-linking treatment. In traditional POF shrink films, the molecular chains are loosely linked physically and are susceptible to deformation or aging due to environmental factors such as temperature, humidity, and oxidation. Cross-linked POF shrink films, on the other hand, are chemically cross-linked or physically cross-linked to strengthen the connections between the molecular chains, making them more resistant to heat, water, tears, and oxidation.

Advantages and Features of Cross-Linked POF Heat Shrinkable Film:

Better durability and stability: Cross-linking treatment improves the stability and aging resistance of polyolefin molecular chains, making them more durable and long-lasting. Cross-linked polyolefin shrink film is less likely to deform, tear, or age during shipping, storage, and display, providing better protection for the product.

Faster shrinkage and higher shrinkage rate: Cross-linked polyolefin shrink film has a higher shrinkage rate and faster shrinkage, enabling it to wrap products faster and achieve tighter results, saving time and costs.

Better transparency and gloss: Cross-linked polyolefin shrink film has better transparency and gloss, presenting a clearer, brighter appearance, and enhancing product display and sales value.

Higher strength and toughness: Cross-linked polyolefin shrink film has higher strength and toughness compared to standard polyolefin shrink film, which can better resist external pressure and extrusion and protect products from damage.

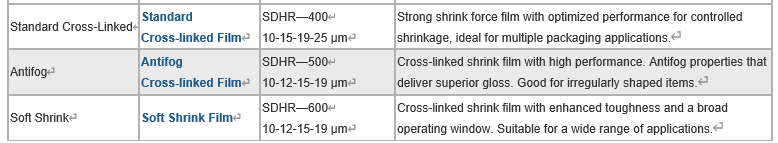

Product Overview:

Our cross-linked polyolefin shrink film is made by using polymers such as polyethylene and polypropylene as raw materials, which are cross-linked through a special process. The film has excellent transparency, shrinkage, strength, and durability, making it widely used in the packaging of food, beverages, pharmaceuticals, cosmetics, daily necessities, electronic products, and other industries.